Mullite and Corundum Mullite Brick

Feature of Corundum Mullite Brick:

High-quality synthetic mullite, high purity corundum as the main raw material, adding special additive, via high pressure molding, the high temperature burn becomes, the product has soft,high porosity Hollywood, low thermal shock performance is good,wear-resisting performance is good wait for a characteristic.

Mullite and Corundum Mullite Brick

| Corundum mullite bricks | Mullite bricks | ||

| Al₂O₃ (%) | ≥ | 80 | 70 |

| Bulk Density (g/cm³) | ≥ | 2.6 | 2.6 |

| Apparent Porosity ( % ) | ≤ | 18 | 18 |

| Cold Crushing Strength (MPa) | 100 | 90 | |

| Thermal Shock Resistance(1000℃,water quenching,cycle) | ≥ | 25 | 25 |

| 0.2MPa Refractoriness Under Load (℃) | ≥ | 1550 | 1500 |

| Thermal Conductivity (700℃,W/m.k)≤ | 2.0 | 1.5 | |

| Rervice Temperature (℃)≥ | ≥ | 1600 | 1550 |

| Refractoriness (℃) | ≥ | 1790 | 1790 |

| Wear-resistance (cm³) | ≤ | 8 | 8 |

Application of Corundum Mullite Brick:

- reverberatory furnace;

- blast furnace;

- shuttle kiln;

- waste incinerator.

Silica Corundum Brick

Features of Silica Corundum Brick:

Requirements for temperature of large and medium-sized rotary kiln cement, metallurgy, meet the needs of required refractory bricks for lime industry featuring volatile temperature and high wear-resistance, high corrosion section, our R&D team took efforts within three years and developed a new product silicon corundum brick.

Silica Corundum Brick

| corundum brick | Silica corundum brick | ||

| LX-SMG-01 | LX-SMG-02 | ||

| Al2O3(%) | 63 | 63 | |

| SiO+SiC(%) | 32 | 32 | |

| Zr2O₃ (%) | 2-5 | 2-5 | |

| Hefractoriness Under Load (0.6 ℃) | ≥ | 1660 | 1660 |

| Cold Crushing Strength (MPa) | ≥ | 100 | 100 |

| 1100℃ Thermal Shock Resistance | 20 | 20 | |

| Bulk Density (g/cm³) | ≥ | 2.7 | 2.7 |

| Thermal conductivity (1000℃)(W/m | ≤ | hot 1.7 cool 1.5 | 1.7 |

Chrome Corundum Brick

Features of Chrome Corundum Brick:

Erosion/Corrosion-resistance, high temperature and other characteristics.Mainly used in lead and zinc smelting furnace, including electric furnace, rotary kiln, electric front bed, reflective furnace,etc..

Chrome Corundum Brick

| GY-1 | ||

| Al₂O₃% | ≥ | 78-83 |

| Cr₂O₃%≥ | ≥ | 10-15 |

| Fe₂O₃% | ≤ | 0.3 |

| SiO2% | ≤ | 0.3 |

| Refractoriness ℃ | ≥ | 1800 |

| Bulk densityg /cm³ | ≥ | 3.35 |

| Cold crushing strength MPa | ≥ | 80 |

| Refractoriness Under Load 0.2MPa℃ | ≥ | 1600 |

| Apparent porosity % | ≤ | 16 |

Sintered Zirconim Corundum Brick

Feature of Sintered Zirconim Corundum Brick:

High softening temperature under load, good thermal shock resistance, high mechanical strength at room temperature and high temperature, wear resistance, the brick is characterized by dense crystal structure, good thermal conductivity, and excellent resistance to slag erosion.

Sintered Zirconim Corundum Brick

| AZS-30 | AZS-20 | ||

| ZrO2% | ≥ | 30 | 20 |

| Al₂O₃% | ≥ | 38 | 45 |

| Fe₂O₃% | ≤ | 1.0 | 1.0 |

| SiO2% | ≤ | 25 | 22 |

| Bulk density g/cm³ | ≥ | 3.3 | 3.2 |

| Cold crushing strength MPa | ≥ | 100 | 100 |

| Refractoriness Under Load 0.2MPa℃ | ≥ | 1680 | 1680 |

| Apparent porosity % | ≤ | 18 | 18 |

Application of Sintered Zirconim Corundum Brick:

- heating furnace;

- glass melting kiln;

- calcium carbide furnace.

Composite Corundum Brick

Features of Composite Corundum Brick:

This product by fused corundum as main raw materials, the high-pressure forming, high temperature firing, have high thermal shock stability, low porosity dykes and low inflation, resistance to melt steam and gas erosion performance is good, oxidation resistance is fine, the size is exact.

Composite Corundum Brick

| Al₂O₃ (%) | ≥ | 78 |

| SiC(%) | ≥ | 14 |

| Fe2O3(%) | ≤ | 1.0 |

| Apparent Porosity (%) | ≤ | 3.0 |

| Bulk Density (g/cm³) | ≥ | 3.0 |

| Cold Crushing Strength (MPa) | ≥ | 100 |

| Refractoriness Under Load 0.2MPa(℃) | ≥ | 1700 |

| (1500℃×2h,%) Refiring linear change | 0~+0.2 |

What is the Price of Corundum Bricks Price?

The main factors affecting the price include: quantity and type. Corundum bricks are key components for building kilns. Lianxin team will provide different pricing plans according to the different needs of customers. The price of corundum bricks varies depending on the quantity and model selected. Customers who order large quantities of the same model can enjoy greater discounts.

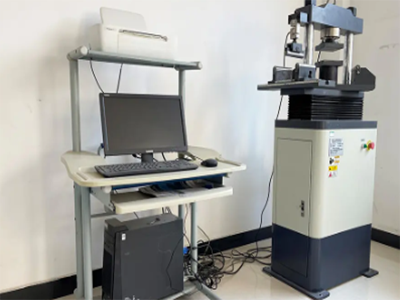

Manufacturing Process of Lianxin Refractory Brick

About Lianxin:

The company has more than 20 patented technologies, more than 20 corporate honors, and international certifications such as ISO. With an annual output of 300,000 tons, the company is a leader in China’s refractory industry. As a manufacturer, we will provide you with factory direct prices. With more than 20 years of experience and a team of more than 200 professionals, we are committed to helping you find a solution that suits your needs.

Why Choose Us?

- Free consultation and free quote

- High quality and source factory price

- Professional kiln design solution

- Professional kiln construction experience and technical guidance

- Fast delivery and after-sales maintenance

Customer Cases of Lianxin

Cooperation Partners